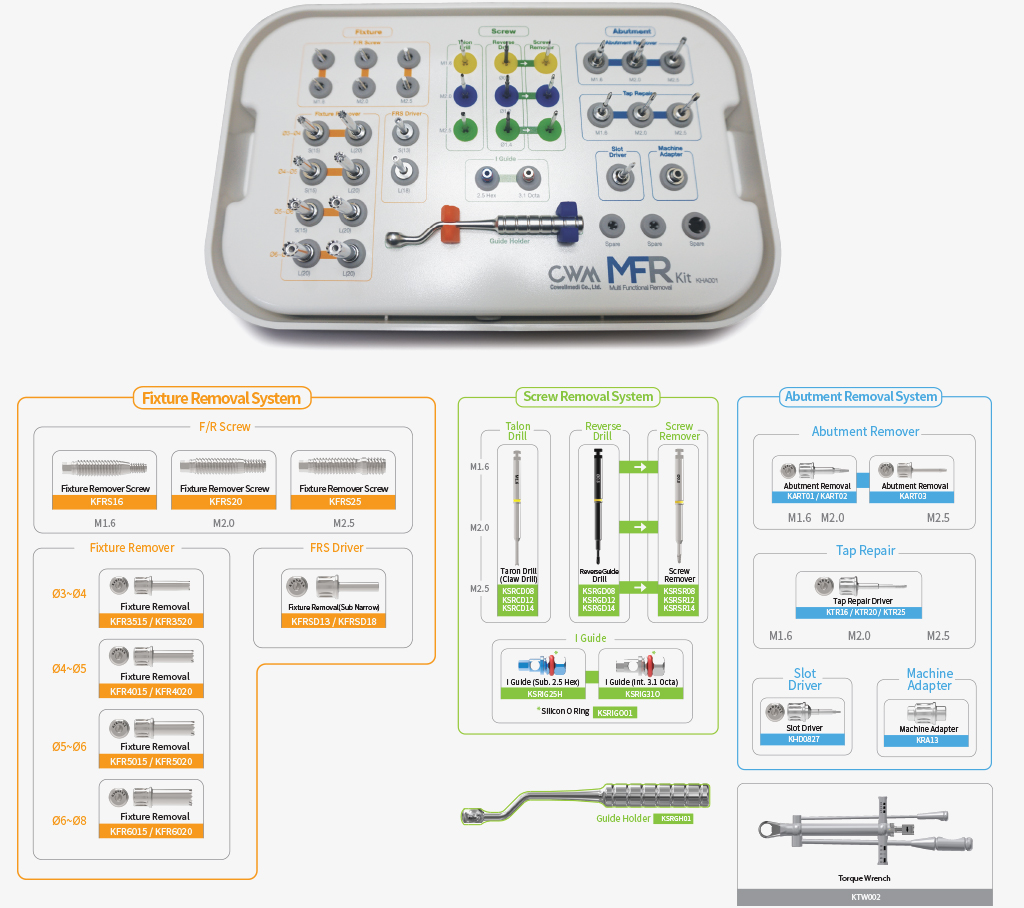

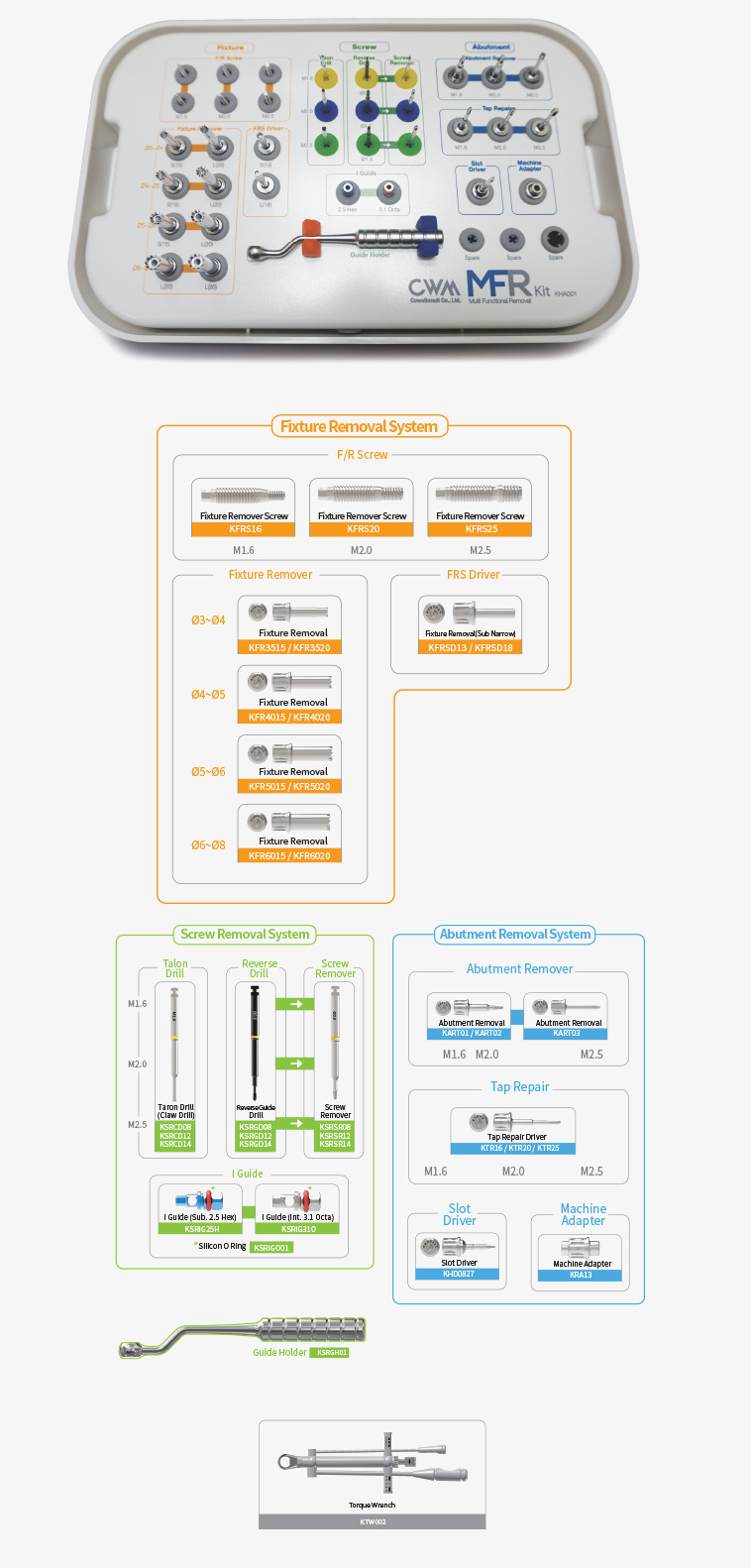

MFR KITMulti Functional Removal [KHA001]

Easy Removal of fractured Fixture / Screw / Abutment

MFR Kit Composition - Middle Tray

MFR Kit Components

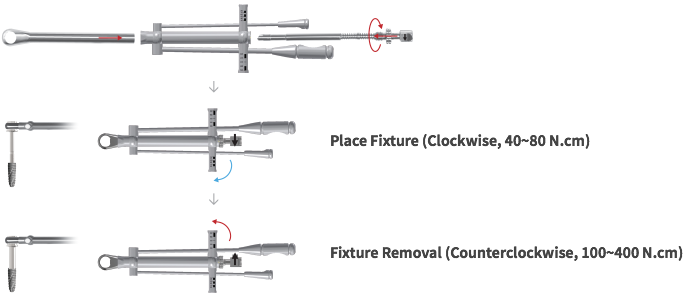

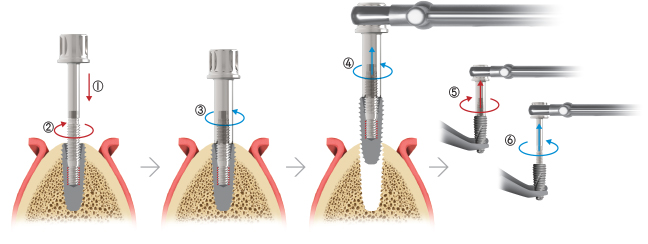

1. Fixture Removal System

- ① Connect the F/R Screw to the FRS Driver.

- ② Connect the F/R Screw mounted FRS Driver to the fixture (clockwise 40~60 N.cm) and remove the FRS Driver.

- ③ Connect the Fixture Remover to the F/R Screw (counterclockwise).

- ④ Remove the fixture after connecting the Torque Wrench (counterclockwise, 100~400 N.cm).

- ⑤ To remove the fixture from the Fixture Remover, use such device as vise to fix the Fixture Remover and connect to the Torque Wrench.

- ⑥ After connecting the FRS Driver to the F/R Screw, use the Torque Wrench to remove the F/R Screw (counterclockwise).

- ※ One-time use of the F/R Screw is recommended (bending or fracture may happen if more than 100 N.cm and using twice may be possible if less than 100 N.cm).

- ※ Sufficient Irrigation required when removing fixture.

- ※ When the maximum torque is exceeded, the fixture may be bent or fractured.

- ※ If fixture can not be removed even with maximum torque,

remove Fixture Remover & F/R Screw, remove bones around fixture while using Round Bur and retry to remove.

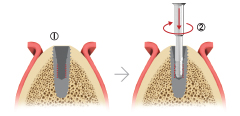

2. Screw Removal System

Talon Drill

- ① Check the broken screw size inside the fixture

- ② Connect the I Guide corresponding to the fixture to the Guide Holder and fasten to the fixture.

- ③ Insert the Talon Drill into the I Guide Hole.

- ④ Remove the screw by pressing force (counterclockwise, 60 ~ 80 rpm).

※ If the I Guide and fixture could not be correctly connected, the path is not correct.

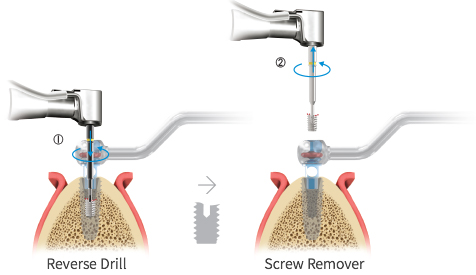

Reverse Drill & Screw Remover

If the screw could not be removed by the Talon Drill

- ① Form the hole on the fractured screw (depth 1 ~ 2mm / counterclockwise / 1,200 ~ 1,400 rpm).

- ② Use Screw Remover according to the created drill hole, remove the screw by pressing force (counterclockwise, 80 N.cm).

- ※ If the path of the I Guide and fixture did not match, It would be difficult to remove the screw because the drill hole is away from the center of the screw.

- ※ Reverse drilling requires removal of chips by irrigation & suction.

- ※ The fractured screw may be removed during reverse drill hole creation.

- ※ If necessary, fasten to the Machine Adapter and use the hand or Torque Wrench.

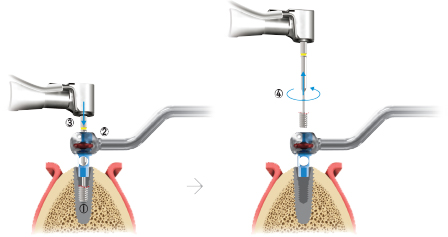

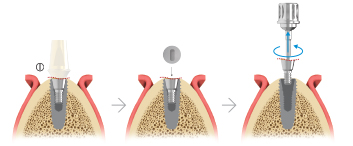

3. Abutment Removal System

Abutment Remover

- ① Used when 2 piece type abutment is fractured.

- ② Connect to the Abutment Remover (clockwise).

- ③ Connect correctly and wiggle to left and right side.

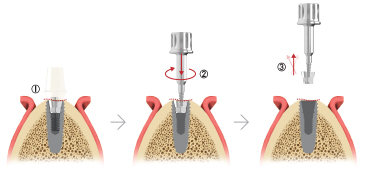

Tap Repair

- ① Used when the thread inside the fixture is occluded and damaged.

- ② Reproduce the thread using the Tap Repair.

Slot Driver

- ① Used for the damaged solid abutment (1 piece type), healing abutment and cover screw.

- ② Form a slot on the surface of the damaged abutment using round bur.

- ③ Connect the Slot Driver to the formed slot and remove it (counterclockwise).

4. Torque Wrench